Timeline

1903

Ford Motor Company founded; Tenvoorde Ford dealership established in St. Cloud

1903

1908

Model T introduced

1908

1911

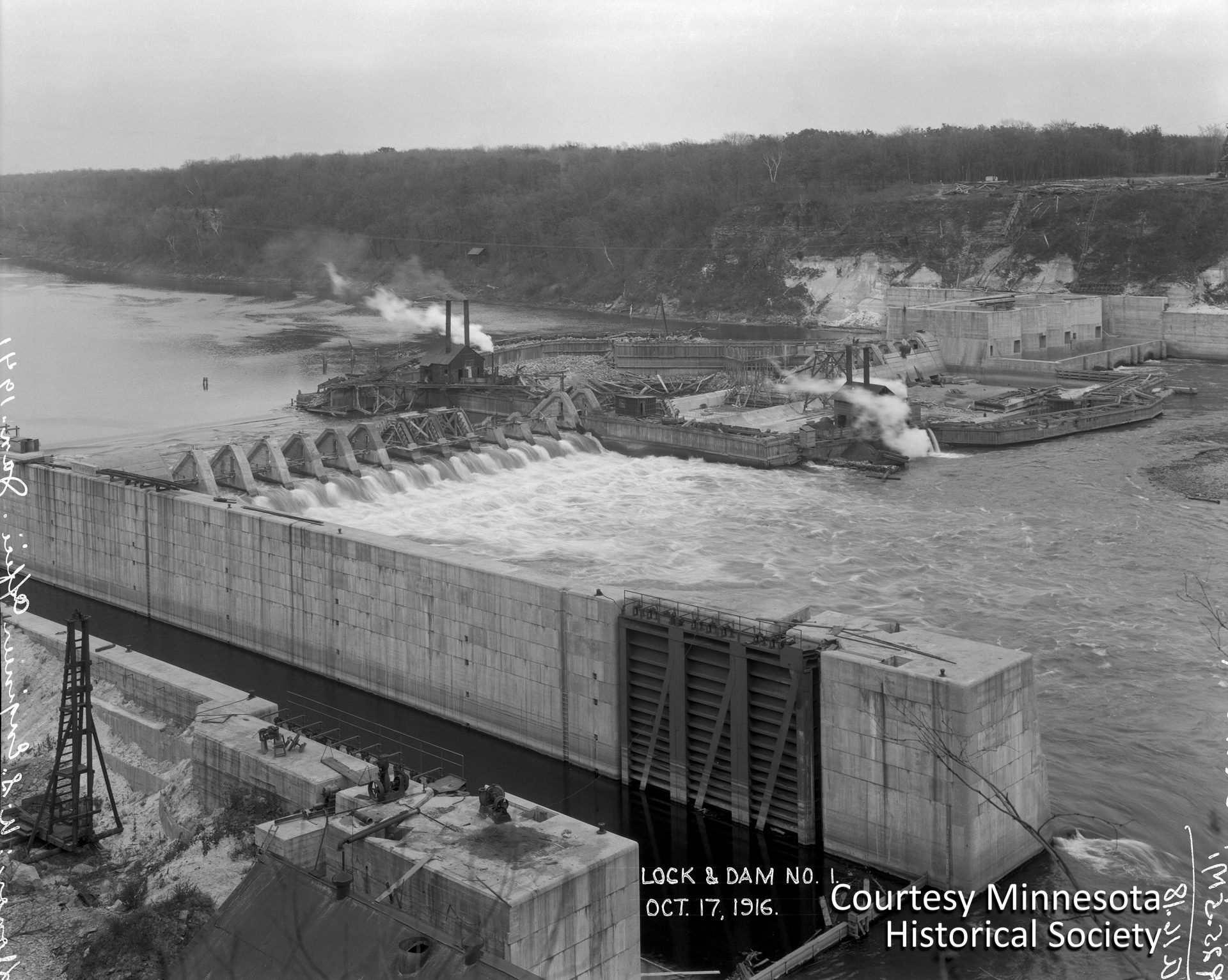

Army Corps of Engineers starts construction on Lock and Dam No. 1

1911

1912

Ford starts assembling Model T’s at 616 S. Third Street, Minneapolis

1912

1913

Ford experiments with assembly line in Highland Park plant, Michigan

1913

1914

Ford opens new 10-story Minneapolis plant

1914

1917

Lock and Dam No. 1 completed at High Dam; U.S. enters WWI

1917

1921

St. Paul applies for permit to develop hydroelectric power at High Dam; 5 millionth Ford car built

1921

1923

Federal Power Commission awards Ford permit for hydropower at High Dam (over objections of Minneapolis); Henry Ford, Edsel Ford and other officials tour St. Paul site; construction begins on Twin Cities Assembly Plant (TCAP); GM introduces annual model changes

1923

1924

TCAP hydroelectric plant generates electricity

1924

1925

First Model T rolls off TCAP assembly line on May 4; at 840,000 sq ft, it’s the largest Ford plant outside of Detroit. 500,000+ visitors tour plant and grounds

1925

1926

Glass plant operation starts

1926

1927

Model T production stops, Model A starts; Ford Bridge opens

1927

1928

Lane’s Highland Park subdivision put on market

1928

1932

Ford introduces V-8 engine

1932

1933

TCAP closed during Depression; part of site turned into gardens

1933

1934

Federal government refuses to buy Ford vehicles because the company won’t accept the New Deal programs

1934

1935

TCAP reopens

1935

1937

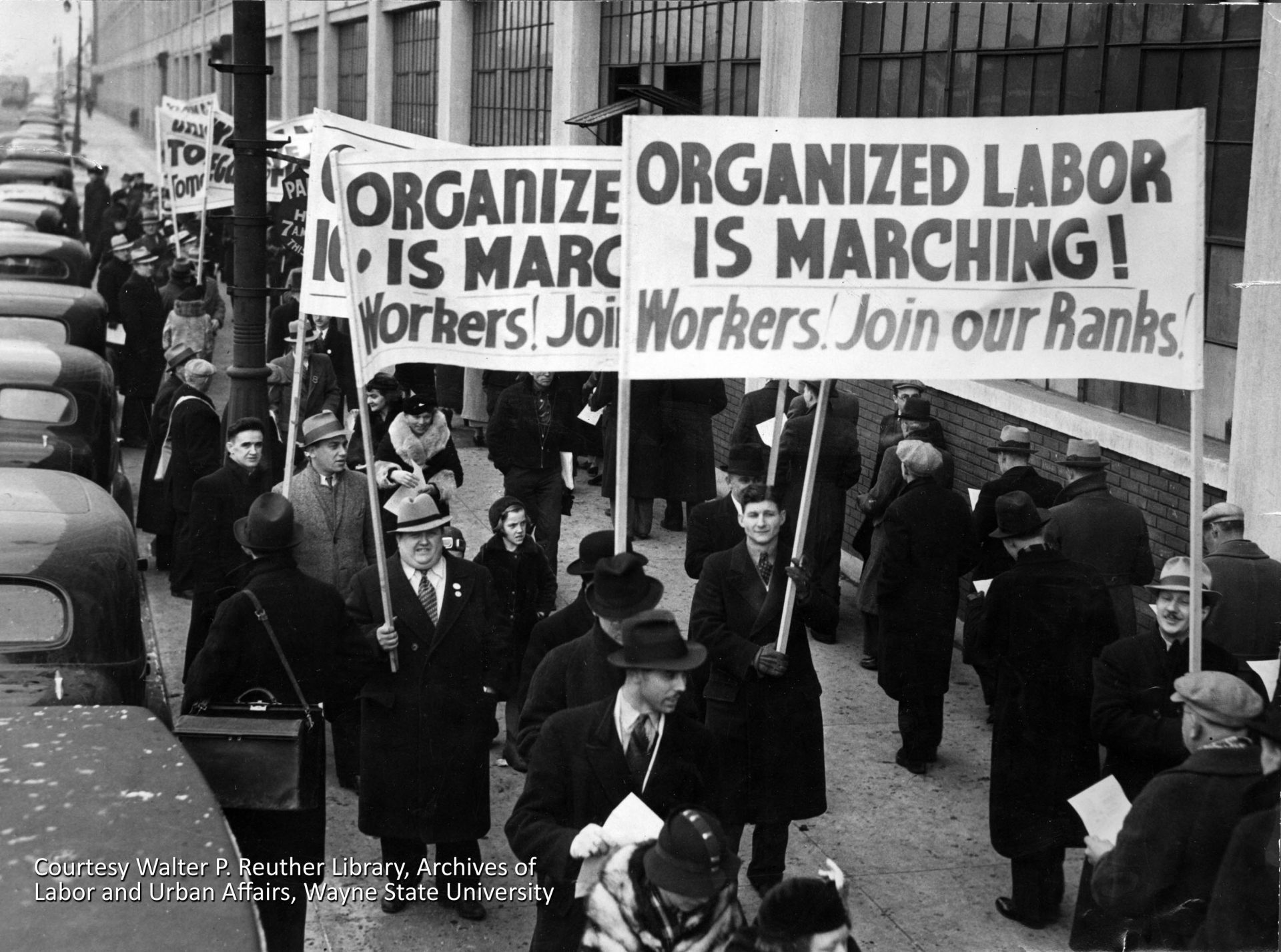

Flint sit-down strike; GM and Chrysler organized; Battle of the Overpass at Ford, May 26

1937

1941

Ford Motor Company organized by UAW; Local 879 forms new charter, July 18; federal government converts auto industry to war production; U.S. enters WWII

1941

1942

TCAP converts to war production; many women recruited; Ford gets order to make M-8 armored vehicle (more than 6,000 would be produced here by 1945)

1942

1943

Edsel Ford dies; Henry assumes presidency

1943

1945

Henry Ford II (the Deuce) becomes president; WWII ends; TCAP resumes civilian production

1945

1946

Walter Reuther elected president of UAW

1946

1947

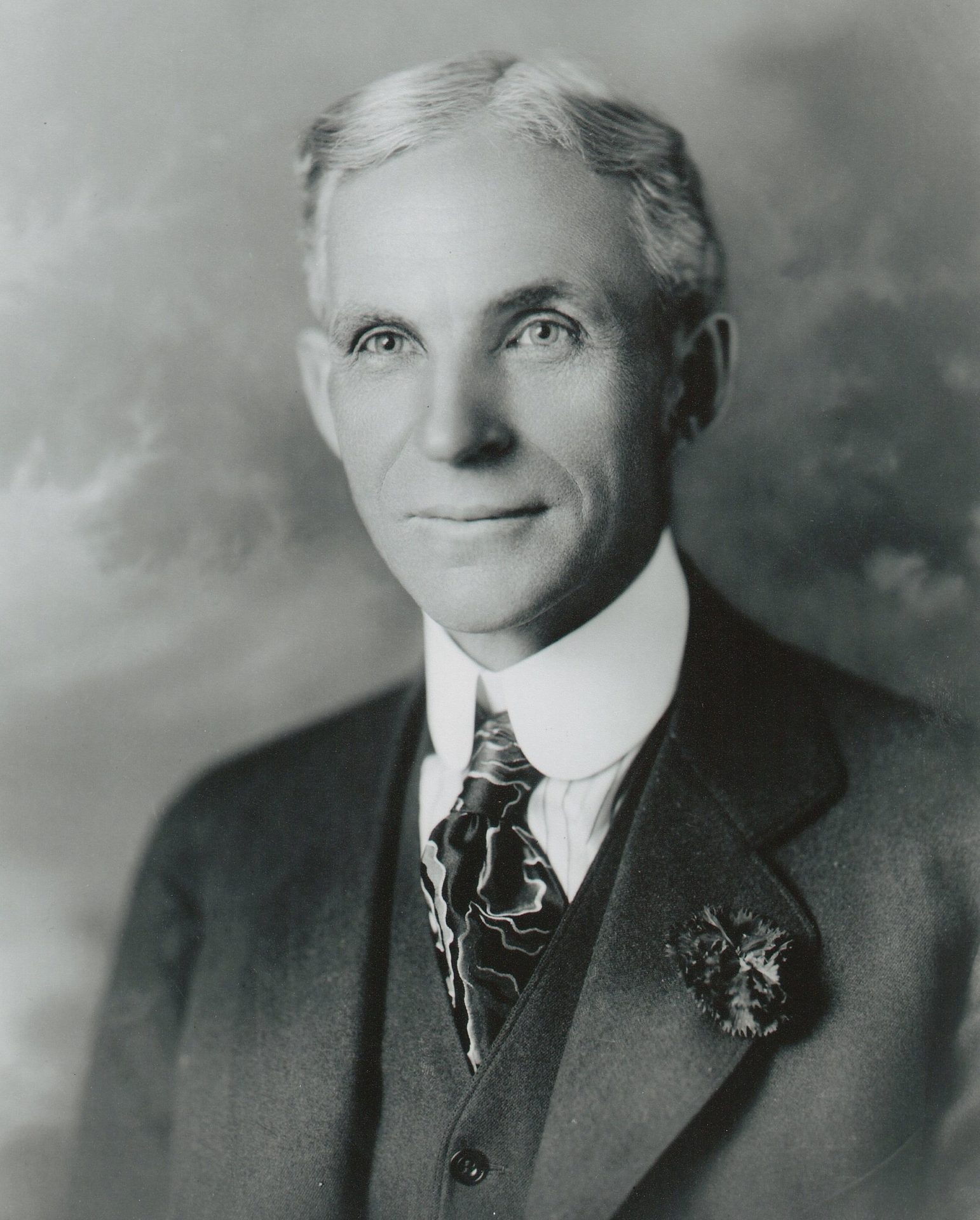

Henry Ford dies, April 7

1947

1949

UAW pushes for expanded social security program; first pension plan for hourly workers; work standards included in contract

1949

1950

UAW strikes Chrysler for 104 days over pensions; Ford passes Chrysler in sales

1950

1952

Flooded Mississippi River knocks out steam and hydro plants

1952

1953

Ford celebrates 50th Anniversary; UAW Local 879 dedicates new hall

1953

1955

Merger of AFL-CIO; George Meany, president; Walter Reuther, V.P.; TCAP produces 130,841 units, a new record

1955

1956

Ford goes public in the largest stock offering ever

1956

1959

Glass plant closes

1959

1965

Mississippi floods again but production uninterrupted; during changeover, skilled workers create fixed-automated welding equipment

1965

1967

National Ford strike lasts 68 days

1967

1969

New plant addition opens

1969

1971

Painting robots introduced early 1970s

1971

1974

Full-size cars not selling well during gas shortage; Ford has first quarterly loss since 1946

1974

1976

Nationwide Ford strike lasts one month; local mood is bitter. New labor agreement includes seven more days off; 4 millionth car made at TCAP; production increases by 20% despite strike: made 84,030 cars and 21,861 trucks

1976

1977

TCAP running 10 hrs/day, 5 days/week; gas rises above .60/gallon.

1977

1978

TCAP converts to all-truck production, adds second shift

1978

1979

UAW Local 879 and national UAW conduct work stoppage to write protest letters to Washington re: oil shortage; Ford loses $678M in third quarter; GM loses $300M; imports rise to 21.8% market share; Federal bailout given to Chrysler; 400 workers fired at TCAP, adding momentum to Unity Caucus, a dissident group; workers bring suit at National Labor Relations Board for labor violations

1979

1980

Ford loses $1.7 billion; Chrysler loses $1.5 billion; Ford commits half its net worth to new Ford Taurus and plant modernizations

1980

1982

For first time in 20 years domestic car production drops below 6 million; nationally, 250,000 autoworkers out of work; imports’ market share rises to 27.9%; Ford loses $658M, pays no dividends; new UAW contract with profit-sharing; locally, Ford celebrates 70th year in Twin Cities

1982

1983

Robots introduced at TCAP

1983

1984

New contract includes more job security, retraining

1984

1985

Two-year, $240M TCAP modernization completed; Ford Ranger production begins; American companies start to shift production to Mexico, years before NAFTA

1985

1987

550,000 Taurus and Sable models sold; for first time in 37 years Ford, beats Chevy; Ford reports highest profits in auto industry: $4.62 billion; Ford workers get largest bonus in industrial history; Ranger becomes best-selling compact truck

1987

1990

TCAP makes 6 millionth vehicle; output averages 900 units a day; TCAP wins prestigious Ford Q1 Award

1990

1992

TCAP suspends popular F-Series to focus on compact Ranger production

1992

1993

TCAP operates on two 10 hour shifts, making 890 Ranger pickups per day; Local 879 organizes national labor conference in St. Paul to discuss globalization

1993

1994

NAFTA goes into effect

1994

1996

Ford plant rates highest in quality – Harbour Report

1996

1999

New Training Center opens at TCAP

1999

2006

State officials travel to Dearborn twice, seeking to prevent plant closing; UAW receives ‘dreaded phone call’ giving notice of plant closing, April 13; Ford starts process of selling off hydroelectric plant

2006

2007

Brookfield Renewable wins bid to acquire hydroelectic plant; City of St. Paul forms task force to explore redevelopment options

2007

2009

GM files for Chapter 11, seeks federal bailout

2009

2011

TCAP closes; plant demolition begins in 2012

2011